The world of high-performance vehicles, long defined by roaring engines and manual gear shifts, is undergoing a radical transformation. What was once a niche driven purely by raw power and mechanical purity is now an intricate blend of cutting-edge technology, sophisticated aerodynamics, and a rapidly accelerating push towards electrification. Performance vehicles are evolving, adapting to new environmental demands, regulatory pressures, and a desire for both exhilarating speed and intelligent efficiency. This isn’t just about faster lap times; it’s about redefining the very essence of performance, integrating advanced software, hybrid powertrains, and even fully electric propulsion to deliver an experience that is at once more potent, more refined, and more connected than ever before. The future of performance is here, and it’s electrifying.

The New Definition of Speed

The evolution of performance vehicles isn’t accidental; it’s propelled by a confluence of powerful forces that are reshaping engineering, design, and consumer expectations.

A. The Electrification Imperative

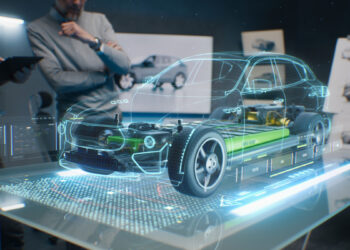

Perhaps the most significant driver of change in the performance segment is the rapid acceleration of electrification. This isn’t just about reducing emissions; it’s about unlocking new levels of performance.

- Instant Torque: Electric motors deliver maximum torque from a standstill, providing instantaneous and breathtaking acceleration that even the most powerful internal combustion engines (ICE) struggle to match off the line. This translates to a sensation of immediate, relentless thrust.

- Enhanced Power Delivery: Hybrid powertrains combine the strengths of both electric motors and gasoline engines, using electric boost to fill in torque gaps, reduce turbo lag, and deliver a seamless surge of power across the entire RPM range.

- Lower Center of Gravity: The heavy battery packs in electric and hybrid performance vehicles are often integrated into the floor, creating an incredibly low center of gravity. This significantly improves handling, cornering stability, and reduces body roll.

- Regenerative Braking: Electric motors can act as generators during braking, recovering kinetic energy and feeding it back into the battery. This not only enhances efficiency but also allows for more aggressive and consistent braking performance, especially on a track.

- Reduced Emissions: While performance cars are often associated with high emissions, electrification helps them meet increasingly stringent global environmental regulations, ensuring their continued relevance in a carbon-conscious world.

- New Soundscapes: While the roar of an ICE engine is iconic, electric performance cars offer a different auditory experience – a futuristic hum, coupled with exhilarating G-forces, proving that performance doesn’t solely rely on traditional engine noise.

The shift to electric and hybrid power is not just a compromise for performance vehicles; it’s a profound enabler of new dynamic capabilities.

B. Advanced Software and AI Integration

Performance vehicles are no longer purely mechanical marvels; they are sophisticated computers on wheels, with software and Artificial Intelligence (AI) playing an increasingly vital role in optimizing every aspect of their operation.

- Predictive Performance Management: AI algorithms analyze real-time data from sensors (tire grip, suspension travel, driver inputs) to predict optimal power delivery, braking points, and even suggest ideal racing lines on a track.

- Active Aerodynamics: Software controls movable aerodynamic elements (spoilers, diffusers, air vents) to dynamically adjust downforce and drag based on speed, steering input, and braking, optimizing performance for different scenarios.

- Adaptive Suspension and Damping: Electronically controlled adaptive dampers and air suspension systems use AI to instantly adjust ride stiffness and height, providing optimal comfort on the road and maximum stiffness for track performance.

- Torque Vectoring and Electronic Differentials: Sophisticated software precisely distributes power to individual wheels, enhancing traction, agility, and stability, allowing the car to “pivot” through corners more effectively.

- Launch Control Optimization: AI fine-tunes traction control, engine RPM, and clutch engagement for perfect, repeatable launches, maximizing acceleration from a standstill.

- Telematics and Data Logging: Connected car technology allows for extensive data logging of performance metrics, lap times, and driver inputs, which can be analyzed by AI to help drivers improve their skills.

- Over-the-Air (OTA) Updates: Performance enhancements, new features, and software fixes can be pushed remotely to the vehicle, continuously improving its capabilities and keeping it cutting-edge.

Software is now as crucial as horsepower in extracting the ultimate performance from these machines.

C. Lightweighting and Material Science Breakthroughs

Every gram saved translates to improved performance. The relentless pursuit of lightness drives innovation in material science and manufacturing.

- Carbon Fiber Composites: Once exclusive to Formula 1 and hypercars, carbon fiber reinforced polymers (CFRP) are increasingly used for chassis components, body panels, and structural elements due to their incredible strength-to-weight ratio.

- Advanced Aluminum Alloys: High-strength, lightweight aluminum alloys are extensively used for chassis, suspension components, and engine blocks, often bonded or riveted rather than welded.

- Titanium and Magnesium: These ultra-light metals are used for specialized components like exhaust systems, engine parts, or wheels where maximum weight reduction is critical.

- 3D Printing/Additive Manufacturing: Enables the creation of complex, lightweight, and optimized components that are impossible to produce with traditional methods, often used for prototypes and low-volume production parts.

- Multi-Material Architectures: Strategically combining different materials (steel, aluminum, carbon fiber) within a single structure to achieve optimal balance of weight, rigidity, and crash safety.

- Lightweighting in Electrification: Despite heavy batteries, engineers are finding innovative ways to reduce weight in other areas of electric and hybrid performance vehicles to compensate, such as integrated battery packaging into the chassis.

These material innovations are fundamental to achieving the agile handling and explosive acceleration expected of a performance vehicle.

D. Aerodynamic Prowess

Harnessing airflow is paramount for stability, grip, and speed, particularly as performance levels continue to climb.

- Computational Fluid Dynamics (CFD): Advanced computer simulations allow engineers to precisely model and optimize airflow over and under the vehicle, identifying areas for drag reduction and downforce generation.

- Active Aero Elements: Movable spoilers, wings, diffusers, and air dams dynamically adjust their position to either reduce drag for high top speed or increase downforce for maximum grip in corners or under braking.

- Ground Effect Optimization: Carefully sculpted underbodies and diffusers generate “ground effect” to pull the car to the road, creating significant downforce without large, drag-inducing wings.

- Air Management Systems: Intricate ducting routes airflow to cool brakes, batteries, and engines, while also managing turbulence around the wheels.

- Integration with Design: Aerodynamic efficiency is no longer an afterthought; it’s meticulously integrated into the overall design language of the car, influencing its aesthetic significantly.

- Vortex Generators and Fins: Small, strategically placed elements that manipulate airflow to improve stability or direct air more efficiently.

Sophisticated aerodynamics are vital for keeping these powerful machines planted at high speeds.

E. Driver Customization and Personalization

Modern performance vehicles offer an unprecedented level of adaptability, allowing drivers to tailor the car’s characteristics to their preferences or specific driving conditions.

- Selectable Driving Modes: Multiple modes (e.g., Comfort, Sport, Track, Race) instantly adjust engine response, transmission shifts, suspension stiffness, steering weight, exhaust note, and traction control settings.

- Individual Component Adjustment: Beyond modes, some high-end performance cars allow granular control over individual parameters like damper stiffness, differential lock, or even brake bias.

- Personalized Performance Profiles: Drivers can often save custom configurations that match their preferred driving style or specific track settings.

- Customizable Digital Displays: Digital instrument clusters and infotainment screens can be configured to display track-specific data, lap timers, G-force meters, and performance graphs.

- Ergonomic Optimization: Adjustable seating positions, steering wheel reach, and pedal placement ensure optimal driver comfort and control during aggressive driving.

- Sound Customization: Active exhaust systems or synthesized engine sounds in EVs allow drivers to tailor the auditory experience.

This level of personalization enhances the driver’s connection with the vehicle and allows them to extract maximum enjoyment and performance.

New Segments and Challengers

The evolution of performance vehicles is also giving rise to new categories and redefining existing ones, with fresh players entering the arena.

A. The Rise of Performance Hybrids and EVs

While traditional supercars still exist, electrified performance is rapidly gaining dominance.

- Hybrid Hypercars: Vehicles like the Mercedes-AMG ONE, Ferrari SF90 Stradale, and McLaren Artura demonstrate how hybrid powertrains can deliver mind-boggling power figures and incredible efficiency, bridging the gap between road and race car.

- Electric Super-Sedans and SUVs: Cars like the Tesla Model S Plaid, Lucid Air Sapphire, and Porsche Taycan Turbo S prove that electric power can deliver instantaneous, brutal acceleration in practical, luxurious packages, challenging traditional performance car norms.

- Dedicated Electric Performance Brands: New companies are emerging solely focused on high-performance electric vehicles, unburdened by legacy ICE infrastructure or design constraints.

- Track-Focused Electric Concepts: Visionary concepts hint at a future where electric vehicles, purpose-built for the track, offer unparalleled performance with zero emissions.

Electrification is expanding the definition of what a performance vehicle can be.

B. Performance SUVs and Crossovers

The popularity of SUVs has inevitably spilled over into the performance segment, creating a new breed of high-riding, high-powered machines.

- “Super-SUVs”: Vehicles like the Lamborghini Urus, Aston Martin DBX 707, Porsche Cayenne Turbo GT, and Ferrari Purosangue offer sports car levels of power and sophisticated handling in a more versatile, family-friendly package.

- Blended Performance: These vehicles often incorporate advanced technologies like active anti-roll bars, torque vectoring, and adaptive air suspension to counteract their higher center of gravity and deliver surprising agility.

- Practicality with Power: They appeal to buyers who want the commanding presence, passenger space, and cargo capacity of an SUV without sacrificing exhilarating performance.

- Growing Segment: This is one of the fastest-growing niches in the performance market, attracting a wide range of buyers.

Performance SUVs represent a compromise-free option for those seeking both thrills and utility.

C. Driver-Focused Purity (The Analog Revival)

Despite the technological onslaught, a small but passionate segment of the market cherishes the raw, unadulterated driving experience.

- Manual Transmissions: A conscious effort by some manufacturers (e.g., Porsche, BMW, Mazda) to continue offering manual transmissions in performance models for ultimate driver engagement.

- Lightweighting for Purity: Stripping out non-essential features and maximizing power-to-weight ratio for a more visceral, uncompromised driving feel.

- Less Electronic Intervention: Tuning traction and stability control systems to allow for more driver involvement and a higher threshold for intervention.

- Limited Production Runs: Catering to enthusiasts and collectors who value rarity and a connection to traditional driving dynamics.

- Focus on Handling: Prioritizing chassis balance, steering feel, and mechanical grip over sheer horsepower figures.

This “analog revival” provides a counterpoint to the high-tech evolution, ensuring diversity in the performance landscape.

Challenges and Opportunities

The evolving landscape of performance vehicles presents both significant hurdles and exciting prospects for manufacturers and consumers alike.

A. Balancing Performance with Sustainability

The primary challenge is reconciling the thirst for power and speed with the urgent need for environmental responsibility.

- Emissions Compliance: Meeting increasingly stringent global emissions standards for ICE vehicles, driving the adoption of more complex and expensive exhaust aftertreatment systems, or pushing for electrification.

- Battery Weight and Cooling: Managing the weight of large battery packs in EVs and hybrids, and effectively cooling them during extreme performance driving, remains an engineering challenge.

- Raw Material Sourcing: Ensuring ethical and sustainable sourcing of critical minerals (lithium, cobalt, nickel) for performance EV batteries.

- Recycling and End-of-Life: Developing robust, cost-effective methods for recycling high-performance EV batteries at the end of their automotive life.

- Carbon Footprint of Production: Reducing the environmental impact of manufacturing specialized components and the energy-intensive production of high-performance vehicles.

The industry must innovate to ensure that performance remains thrilling without compromising the planet.

B. The Emotional Connection of Electrified Performance

A key challenge for electric performance vehicles is replicating the emotional connection that many enthusiasts have with the sound and feel of a powerful ICE engine.

- Auditory Experience: Developing compelling synthetic sounds or enhancing natural electric motor sounds to provide sensory feedback to the driver.

- Vibration and Tactile Feedback: Replicating the subtle vibrations and tactile sensations that contribute to the “feel” of a high-performance gasoline engine.

- Shift Shock: Recreating the engaging sensation of gear changes (even simulated ones) in multi-speed electric transmissions.

- Weight Perception: Engineering lightweight structures and advanced suspension to make heavy EVs feel nimble and agile.

- Charger Anxiety: For track use, rapid battery depletion and the need for high-power, fast-charging infrastructure at circuits are significant considerations.

Manufacturers are working to define a new “electric performance language” that resonates with enthusiasts.

C. Cyber Security and Software Complexity

As performance vehicles become more software-defined and connected, new vulnerabilities emerge.

- Cyber Threats: Protecting complex software systems from hacking, which could compromise vehicle performance, safety, or data.

- Software Glitches: The increased complexity of software means a higher potential for bugs or glitches that could affect performance or reliability.

- Over-the-Air Update Reliability: Ensuring that OTA updates are secure, stable, and do not introduce unintended consequences.

- Data Privacy: Managing the vast amounts of performance and driver data collected by connected vehicles, ensuring privacy and ethical use.

Robust cybersecurity and rigorous software testing are paramount.

D. Cost and Accessibility

High-performance vehicles, especially those with advanced electrification, often come with a substantial price tag.

- Development Costs: The immense R&D investment in new battery tech, advanced materials, and complex software drives up production costs.

- Component Costs: Specialized high-performance components (carbon-ceramic brakes, bespoke suspension) are inherently expensive.

- Exclusivity vs. Volume: Balancing the desire for exclusivity and high margins with the need to achieve economies of scale for electrification.

- Charging Infrastructure for EVs: The need for significant investment in high-power charging infrastructure at homes and public places to support performance EVs.

Making high performance more accessible, while retaining its exclusivity, is a constant balancing act.

E. Infrastructure for Track Use

For those who use performance vehicles as intended on a track, the shift to EVs brings specific infrastructure demands.

- High-Power Charging at Tracks: Circuits will need significant upgrades to their electrical grids to support numerous high-power EV charging stations simultaneously.

- Battery Degradation on Track: Sustained high-performance driving can generate significant heat, potentially accelerating battery degradation if not managed effectively.

- Cool-Down Protocols: New procedures for cooling batteries after strenuous track sessions.

- Battery Swapping: Exploring battery swapping concepts for track applications to minimize downtime.

The interaction between EV performance and track day infrastructure is a growing area of focus.

Conclusion

The landscape of performance vehicles is evolving at an unprecedented pace, driven by a powerful synergy of electrification, intelligent software, advanced materials, and sophisticated aerodynamics. What was once defined by brute force is now characterized by precise control, instantaneous power, and a refined, connected driving experience. While the iconic roar of the internal combustion engine may gradually recede, its spirit of exhilaration and engineering mastery is finding new expression in the silent, powerful thrust of electric motors and the intelligent orchestration of advanced algorithms. The challenges are formidable, but the opportunities for innovation are even greater. The future promises a diverse array of high-performance machines that are not only faster and more capable than ever before, but also more sustainable, more intelligent, and more deeply integrated into the evolving world of mobility. The thrill ride, it seems, is only just beginning.