How Hydrogen Fuel Cells Work and Their Unique Promise

To evaluate the hype, it’s crucial to understand the fundamental principles behind hydrogen fuel cell technology and what makes it distinct from battery electric vehicles.

A. The Electrochemical Process

A hydrogen fuel cell operates as an electrochemical device that converts the chemical energy of hydrogen and oxygen into electricity, with water as the only byproduct. Unlike a battery, a fuel cell does not “run down” or need recharging; it produces electricity as long as fuel (hydrogen) and an oxidant (oxygen from the air) are supplied.

- Anode (Negative Electrode): Hydrogen gas () is fed into the anode. A catalyst (typically platinum) separates the hydrogen atoms into protons () and electrons ().

- Electrolyte Membrane: A proton exchange membrane (PEM) – a specialized material – allows only the protons to pass through it to the cathode. The electrons, however, are forced to take an external circuit, creating an electric current that powers the electric motor(s) of the vehicle.

- Cathode (Positive Electrode): Oxygen gas () from the air is fed into the cathode. Here, the electrons, having traveled through the external circuit, recombine with the protons that passed through the membrane and with oxygen to form water () and heat.

- Byproduct: The only direct emissions from a hydrogen fuel cell vehicle (FCV) are pure water vapor and heat. There are no greenhouse gases, no particulate matter, and no air pollutants released from the vehicle itself.

- Onboard Storage: Hydrogen is typically stored in highly pressurized tanks (700 bar or approximately 10,000 psi) within the vehicle. These tanks are designed to be extremely robust and safe, undergoing rigorous testing.

This elegant chemical reaction provides a continuous supply of electricity without combustion, offering a fundamentally clean energy source at the point of use.

B. Key Differentiators from Battery Electric Vehicles (BEVs)

While both FCVs and BEVs are zero-emission at the tailpipe and use electric motors, their underlying energy storage and delivery mechanisms are vastly different, leading to unique advantages for FCVs.

- Refueling vs. Recharging:

- FCVs: Refuel with hydrogen gas in a process similar to pumping gasoline, typically taking 3-5 minutes for a full tank.

- BEVs: Recharge their batteries, which can take from 20 minutes (DC fast charging) to many hours (Level 2 AC charging), depending on the charger and battery size.

- Range:

- FCVs: Can achieve ranges comparable to or exceeding gasoline vehicles (e.g., 300-400+ miles) on a single fill-up, even for larger vehicles. The range is less impacted by external temperature fluctuations compared to current BEVs.

- BEVs: Ranges vary widely, but for very long distances or heavy loads, large battery packs become very heavy and expensive. Cold weather can also significantly reduce BEV range.

- Weight:

- FCVs: Hydrogen fuel cell systems and tanks are generally lighter than large battery packs required for equivalent range in heavy-duty applications. This allows for higher payload capacity, which is crucial for commercial vehicles.

- BEVs: Large battery packs can add significant weight to a vehicle, impacting efficiency and payload.

- Payload and Towing:

- FCVs: Their lighter powertrain and quick refueling make them well-suited for heavy-duty applications like long-haul trucking, buses, and trains, where weight and downtime are critical factors.

- BEVs: While powerful, the weight of their batteries can limit payload and range when towing or carrying heavy loads.

- Energy Density of Fuel:

- FCVs: Hydrogen, though challenging to store, has a very high energy density by weight, meaning a small amount of hydrogen can store a lot of energy.

- BEVs: Batteries have a lower energy density by weight compared to liquid fuels or compressed hydrogen.

- Scalability:

- FCVs: The infrastructure for hydrogen can be scaled for large vehicles and heavy-duty applications, making it suitable for industrial uses beyond personal transport.

- BEVs: Scaling battery capacity for very large vehicles often leads to prohibitive costs, weight, and charging times.

These inherent differences position hydrogen fuel cells as a compelling, complementary solution to BEVs, particularly for applications where long range, quick refueling, and high payload capacity are critical.

The Drivers of Current Interest

Despite past setbacks and skepticism, the current renewed interest in hydrogen fuel cell technology is driven by several converging factors.

A. Push for Heavy-Duty and Commercial Applications

This is where hydrogen is gaining the most traction and where its unique advantages truly shine.

- Long-Haul Trucking: Electric trucks with massive batteries face challenges with range, charging time (which means significant downtime for drivers), and payload limitations due to battery weight. FCEVs offer range and refueling times comparable to diesel trucks, making them highly attractive for logistics companies.

- Buses and Coaches: Urban buses and intercity coaches benefit from quick refueling, allowing them to maintain consistent routes without lengthy charging stops, maximizing operational time.

- Trains: Hydrogen-powered trains are emerging as a clean alternative for non-electrified rail lines, offering zero emissions without the need for extensive overhead catenary systems.

- Maritime Shipping: The shipping industry is exploring hydrogen (and ammonia derived from hydrogen) as a future fuel to decarbonize large vessels, which require immense energy density for long voyages.

- Industrial Vehicles: Forklifts, port equipment, and other heavy industrial machinery can benefit from quick hydrogen refueling and continuous operation in demanding environments.

- Reduced Downtime: For commercial fleets, every minute a vehicle is not operating means lost revenue. Quick refueling dramatically reduces downtime compared to prolonged charging.

This focus on heavy-duty applications is a more pragmatic and promising direction than previous attempts to push hydrogen solely for passenger cars.

B. Global Decarbonization Goals and Energy Security

Hydrogen is increasingly seen as a crucial component of a broader energy transition strategy.

- Versatile Energy Carrier: Hydrogen can be produced from diverse energy sources (renewable electricity, natural gas with carbon capture) and used in various sectors (transport, industry, power generation), making it a versatile tool for decarbonization.

- Long-Term Energy Storage: Hydrogen can store excess renewable energy (e.g., from solar or wind farms) that would otherwise be curtailed, providing a way to use intermittent renewable sources more effectively. This is key for grid stability.

- Industrial Decarbonization: Hard-to-abate sectors like steelmaking, cement production, and chemical manufacturing, which rely on high heat and chemical processes, can replace fossil fuels with green hydrogen.

- Energy Security: Producing hydrogen domestically reduces reliance on imported fossil fuels, enhancing national energy security.

- Governmental Roadmaps and Investment: Many countries (e.g., Germany, Japan, South Korea, Australia, the EU, the US) have launched national hydrogen strategies and committed significant funding to develop hydrogen production, infrastructure, and end-use applications.

- Power-to-X: The concept of converting surplus renewable electricity into hydrogen, which can then be converted into synthetic fuels (e-fuels), ammonia, or other chemicals for various applications.

Hydrogen’s role in the broader energy ecosystem, not just transport, is boosting its profile.

C. Advancements in Hydrogen Production

The “green” credentials of hydrogen largely depend on how it’s produced. Innovation in this area is critical.

- Green Hydrogen (Electrolysis): The most sustainable method, using renewable electricity (solar, wind) to split water into hydrogen and oxygen. Advances in electrolyzer efficiency and cost reduction are making this more economically viable.

- Blue Hydrogen (with Carbon Capture): Producing hydrogen from natural gas while capturing and storing the resulting carbon emissions. This is seen as a transitional solution to scale up hydrogen supply while green hydrogen production ramps up.

- Turquoise Hydrogen (Methane Pyrolysis): A newer method that produces hydrogen and solid carbon (instead of ) from methane, with potentially lower energy requirements.

- Cost Reduction: The drive to reduce the cost of producing green hydrogen to become competitive with fossil fuels is a major area of R&D and investment.

- Scalability: Developing technologies and infrastructure for producing hydrogen at industrial scale to meet future demand across various sectors.

The focus is shifting towards cleaner and more cost-effective production methods to ensure hydrogen is truly sustainable.

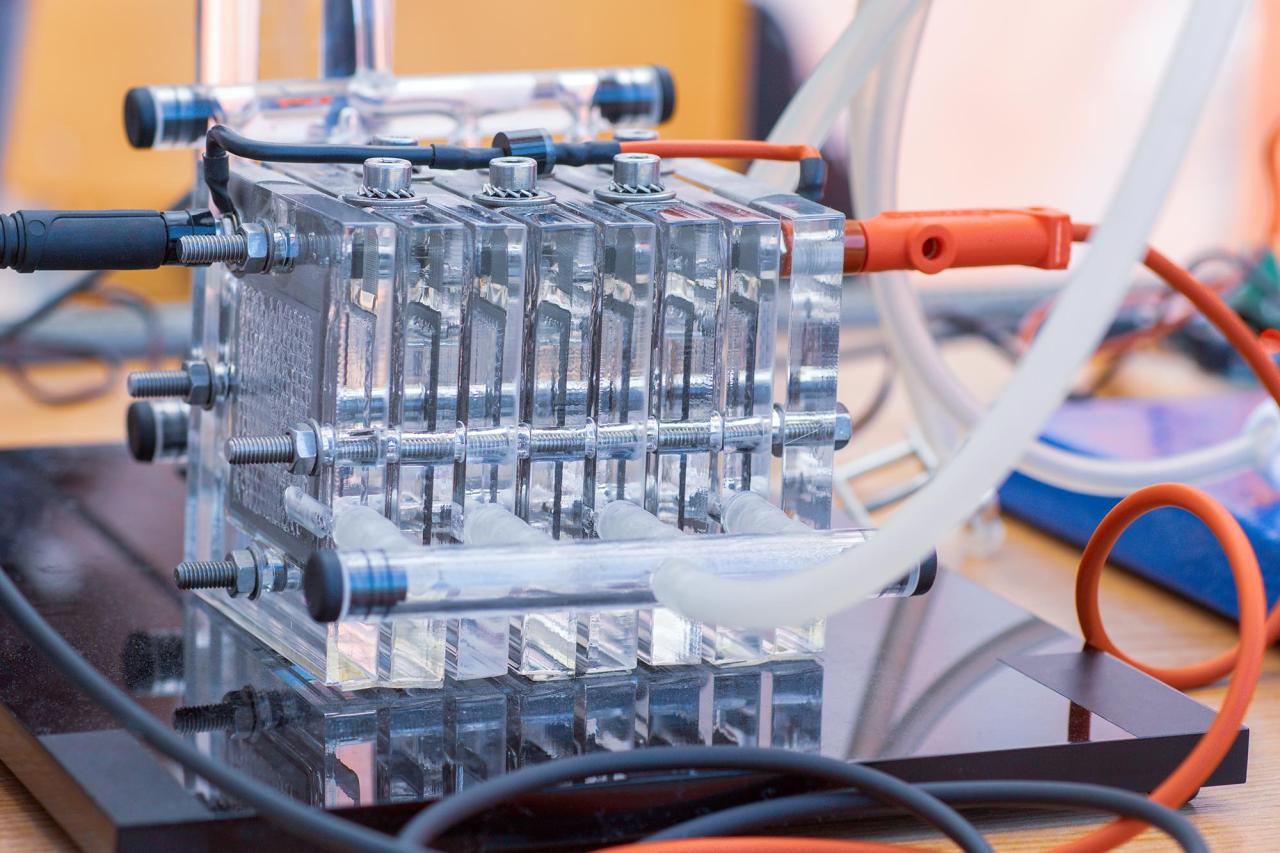

D. Progress in Fuel Cell Technology and Efficiency

The core fuel cell stack itself is also seeing continuous improvement.

- Increased Efficiency: Newer fuel cell designs are more efficient at converting hydrogen to electricity, meaning less hydrogen is needed for the same amount of power.

- Reduced Platinum Usage: Efforts to reduce or even eliminate the reliance on expensive and rare platinum as a catalyst, driving down costs and improving scalability.

- Improved Durability and Lifespan: Fuel cells are becoming more robust and lasting longer, making them more commercially viable for long-term fleet operation.

- Miniaturization and Packaging: More compact and lighter fuel cell stacks allow for easier integration into various vehicle platforms.

- Stack Power Density: Increasing the power output per unit volume or weight of the fuel cell stack.

These improvements make FCVs more reliable and cost-effective.

E. Collaborative Efforts and Cross-Industry Alliances

The complexity of building a hydrogen economy requires collaboration between diverse stakeholders.

- Automakers and Fuel Cell Developers: Partnerships between car manufacturers (e.g., Toyota, Hyundai, Honda) and specialized fuel cell companies (e.g., Ballard Power Systems, Plug Power) to develop and commercialize FCVs.

- Energy Companies and Industrial Players: Major oil & gas companies, utilities, and industrial gas suppliers are investing in hydrogen production, infrastructure, and logistics.

- Government-Industry Partnerships: Public funding and policy support are crucial for de-risking early-stage investments in hydrogen infrastructure.

- International Collaborations: Cross-border projects and agreements to build global hydrogen supply chains and align regulatory standards.

- Hydrogen Councils and Associations: Industry groups formed to advocate for hydrogen, promote R&D, and develop best practices.

These collaborations are essential for building the full hydrogen value chain.

Why the Hype Remains Contested

Despite the renewed optimism, significant challenges remain for hydrogen fuel cell technology to achieve widespread adoption, particularly in the passenger car segment.

A. Infrastructure Development (The “Chicken and Egg” Problem)

This is arguably the most significant hurdle for hydrogen vehicles, especially FCVs.

- Lack of Refueling Stations: Compared to the rapidly growing network of EV charging stations, hydrogen refueling stations are extremely sparse globally. This creates the “chicken and egg” problem: few FCVs are sold because there are few stations, and few stations are built because there are few FCVs.

- High Cost of Stations: Building a hydrogen refueling station is significantly more expensive than building an EV charging station, requiring specialized equipment for hydrogen compression, storage, and dispensing.

- Logistics of Supply: Transporting hydrogen (which is very light by volume) from production sites to refueling stations is complex and costly, whether by pipeline, truck, or rail.

- Energy Loss in Conversion: Producing, compressing, transporting, and then converting hydrogen back into electricity involves multiple energy conversion steps, each with some efficiency losses. This makes the “well-to-wheel” efficiency of FCVs generally lower than BEVs.

- Public Awareness and Acceptance: Many consumers are unfamiliar with hydrogen technology and may have concerns about safety, given its highly flammable nature, despite robust safety testing.

Until a comprehensive and convenient refueling network is established, widespread FCV adoption remains challenging.

B. High Cost of Production and Vehicles

Currently, both hydrogen production and fuel cell vehicles are more expensive than their electric counterparts.

- Cost of Green Hydrogen: Producing green hydrogen (via renewable electricity) is still more expensive than producing hydrogen from fossil fuels or battery electricity. This “green premium” needs to come down significantly.

- Fuel Cell Stack Cost: While platinum usage is being reduced, the manufacturing of fuel cell stacks remains complex and expensive, especially for smaller volumes.

- High-Pressure Storage Tanks: The specialized carbon fiber composite tanks required to safely store hydrogen at high pressure are expensive to produce.

- Lack of Economies of Scale: Due to low production volumes, FCVs currently do not benefit from the same economies of scale as BEVs, which are seeing rapid cost reductions.

- Total Cost of Ownership: While fuel costs might be competitive in some regions, the higher upfront vehicle cost and sparse refueling network still present a barrier for many.

Cost parity with other zero-emission technologies is a major goal that requires further innovation and scaling.

C. Perceived Safety Concerns

Despite rigorous safety testing and engineering, public perception of hydrogen’s flammability remains a hurdle.

- Hindenburg Effect: The historical disaster of the Hindenburg airship has left a lingering public perception of hydrogen as inherently dangerous, despite it being a different application.

- Flammability: Hydrogen is highly flammable. While FCVs are designed with numerous safety features to prevent leaks and mitigate risks (e.g., hydrogen disperses rapidly upwards), public education is needed to address concerns.

- Crashworthiness: Ensuring the integrity of high-pressure hydrogen tanks in the event of a severe collision is paramount and is a key area of safety engineering and testing.

- Lack of Familiarity: Unlike gasoline or electricity, hydrogen is not a commonly encountered fuel for the average person, leading to an understandable degree of apprehension.

Transparent communication about safety standards and real-world performance is vital to build trust.

D. “Green Hydrogen” Scalability

While the promise of green hydrogen is immense, scaling its production globally to meet future demand is a monumental task.

- Renewable Energy Requirements: Producing green hydrogen requires vast amounts of renewable electricity generation, which itself needs significant investment and expansion.

- Electrolyzer Capacity: The manufacturing capacity for electrolyzers (the devices that split water into hydrogen) needs to grow exponentially.

- Water Usage: While water is abundant, large-scale green hydrogen production requires access to significant quantities of pure water, which can be a concern in water-stressed regions.

- Infrastructure Investment: The entire value chain – from production plants to pipelines, storage, and distribution – requires colossal investment.

Scaling green hydrogen production is a long-term endeavor that will take decades to fully realize.

E. Competition from Battery Electric Vehicles (BEVs)

BEVs have a significant head start in the passenger car market and continue to improve rapidly.

- Established Charging Network: The global EV charging network is expanding rapidly, making BEVs increasingly convenient for many drivers.

- Lower Upfront Cost: BEVs are generally becoming more affordable, with many models already at or near price parity with ICE vehicles in some segments.

- Simpler Technology: From a consumer perspective, BEVs are often perceived as simpler, with fewer complex moving parts (though the battery itself is complex).

- Government and Industry Momentum: A large majority of automotive industry investment and government incentives are currently focused on BEVs for passenger transport.

For passenger cars, BEVs currently hold a strong competitive advantage, pushing FCVs to focus on niche or heavy-duty applications where BEVs face greater challenges.

Conclusion

The hydrogen fuel cell hype is not entirely unfounded, nor is it a universal solution. While battery electric vehicles are rapidly establishing dominance in the passenger car market, hydrogen fuel cell technology presents a compelling, often indispensable, solution for specific and critical applications where electrification faces inherent limitations – primarily in long-haul trucking, heavy-duty transport, and industrial processes. The focus has pragmatically shifted from a direct competition with BEVs in every segment to identifying hydrogen’s unique and complementary role in the broader decarbonization strategy. As advancements in green hydrogen production, fuel cell efficiency, and infrastructure development continue, the initial hype may well evolve into a powerful, albeit specialized, reality. Hydrogen is not meant to replace all batteries, but it is poised to fill crucial gaps, ensuring a truly comprehensive and sustainable energy future. The future of mobility and industry will likely be a mosaic of different clean energy solutions, and hydrogen fuel cells are certainly a vibrant piece of that evolving picture.