The relentless pursuit of speed, precision, and victory in motorsports has always been a crucible for cutting-edge technology. What begins on the race track often finds its way into the cars we drive every day, pushing the boundaries of automotive engineering. Today, motorsports tech advances are accelerating at an unprecedented pace, driven by a convergence of electrification, artificial intelligence, advanced materials, and data analytics. This isn’t merely about incremental improvements to internal combustion engines; it’s a fundamental reimagining of how race cars are designed, built, controlled, and even powered. The modern race track is a living laboratory, where innovation is paramount, directly influencing the future of the entire automotive industry and thrilling fans worldwide.

Why Motorsports Drives Innovation

Motorsports, by its very nature, is a hyper-competitive environment that pushes the limits of human and mechanical capability. This extreme pressure cooker environment is the ideal incubator for technological advancement.

A. The Pursuit of Speed and Performance

At the core of motorsports is the unyielding drive to go faster, lap quicker, and accelerate harder.

- Marginal Gains: In highly competitive series like Formula 1, even a tenth of a second per lap can mean the difference between victory and defeat. This incentivizes engineers to meticulously optimize every component for maximum performance.

- Aerodynamic Perfection: The constant battle against air resistance and the quest for optimal downforce pushes the boundaries of aerodynamic design, leading to incredibly complex and efficient bodywork.

- Powertrain Optimization: Every ounce of power is extracted from engines (whether ICE or electric), with a focus on efficiency, reliability, and immediate response, often through hybrid systems.

- Lightweighting Extremes: Every gram matters. The use of exotic, ultra-light, and incredibly strong materials is paramount to improving power-to-weight ratios and agility.

- Chassis and Suspension Dynamics: Fine-tuning the chassis, suspension, and tire interface for maximum mechanical grip and precise handling is an endless endeavor.

This singular focus on performance creates an environment where new technologies are rapidly developed and proven.

B. Safety as a Paramount Concern

While speed is key, ensuring driver safety at extreme velocities is equally important, driving significant safety innovations.

- Carbon Fiber Monocoques: The development of incredibly strong and lightweight carbon fiber safety cells (monocoques) that absorb immense crash energy, protecting the driver.

- HANS Device (Head and Neck Support): Revolutionized driver safety by limiting head movement in a crash, preventing severe neck injuries.

- Impact Absorbing Structures: Designed crumple zones and energy-absorbing materials within the car’s structure to dissipate crash forces.

- Advanced Restraint Systems: Multi-point harnesses and increasingly sophisticated seat designs that securely hold the driver in place during high G-force maneuvers and impacts.

- Track Safety Enhancements: Developments in track design, barrier technology, and rapid response medical teams are also influenced by motorsports safety innovations.

- Telemetry and Remote Monitoring: Real-time monitoring of vehicle parameters and driver biometrics allows teams to detect potential issues and emergency services to react precisely in an incident.

Motorsports continually pushes the boundaries of vehicle and track safety, with benefits often transferring to road cars.

C. Extreme Operating Conditions

Race cars operate at the very limits of their mechanical and thermal endurance, demanding robust and resilient technologies.

- High Temperatures: Engines, brakes, and tires reach extreme temperatures, requiring advanced cooling systems and heat-resistant materials.

- High G-Forces: Drivers and components must withstand tremendous G-forces during acceleration, braking, and cornering, demanding extreme structural integrity.

- Vibration and Stress: Constant high-frequency vibrations and immense mechanical stresses test the durability of every part, from nuts and bolts to complex electronic systems.

- Rapid Cycles: Components are constantly pushed from cold to hot, from static to maximum load, in very short periods, accelerating wear and exposing weaknesses.

This harsh operating environment acts as a rapid-fire stress test for new materials and systems.

D. Rules and Regulations as Catalysts for Innovation

Motorsports governing bodies (like FIA) constantly evolve rules to manage performance, promote safety, and encourage specific technological directions (e.g., hybrid power).

- Engine Formula Changes: Imposing limits on engine size, number of cylinders, or mandating hybrid components forces manufacturers to find innovative ways to extract performance within new constraints.

- Aerodynamic Restrictions: Limiting wing sizes or bodywork dimensions pushes designers to find more efficient ways to generate downforce.

- Cost Controls: Efforts to reduce spending (e.g., budget caps in F1) encourage clever, efficient engineering over brute-force spending.

- Sustainability Mandates: The introduction of sustainable fuels, electric classes, or requirements for energy recovery systems directly drives green technology development.

- Standardization of Components: In some series, standardizing certain parts (e.g., chassis, batteries in spec series) shifts the focus of innovation to other areas, like powertrain integration or tire management.

Regulations, rather than stifling innovation, often redirect it into new and fascinating avenues.

Key Technological Advances in Motorsports

The modern motorsports arena is a showcase of cutting-edge technology, pushing the boundaries in every conceivable area.

A. Hybrid and Electric Powertrains

The electrification revolution is as impactful in motorsports as it is on the road, if not more so.

- Formula 1 Hybrid Power Units: F1’s highly sophisticated hybrid power units combine a V6 turbo-hybrid ICE with multiple Motor Generator Units (MGU-K and MGU-H) to recover energy from braking and exhaust heat. These are among the most thermally efficient engines ever built, directly influencing road car hybrid development.

- Formula E (Electric Single-Seaters): A championship entirely dedicated to electric open-wheel racing, pushing battery technology, electric motor efficiency, and power management systems to their limits.

- Le Mans Hypercar and LMDh Categories: Endurance racing’s top classes mandate hybrid powertrains, focusing on efficiency, reliability, and sustained high power output over many hours.

- Extreme E (Electric Off-Road SUVs): An off-road racing series for electric SUVs, driving advancements in electric powertrains for challenging, varied terrains.

- Instant Torque and Power Delivery: Electric motors provide incredible, immediate torque, fundamentally changing acceleration profiles and traction control strategies.

- Energy Recovery Systems (ERS): Regenerative braking systems are highly optimized to capture maximum energy during deceleration, feeding it back into powerful battery packs or supercapacitors.

Electrification is not just about reducing emissions but about unlocking new levels of performance and efficiency.

B. Advanced Aerodynamics and Computational Fluid Dynamics (CFD)

Airflow management is paramount, with every surface meticulously sculpted for performance.

- Computational Fluid Dynamics (CFD): Sophisticated simulation software allows engineers to precisely model and optimize airflow over and under the car, identifying minute areas for drag reduction and downforce generation, far beyond what wind tunnels alone can achieve.

- Active Aerodynamics: Movable wings, flaps, and diffusers that dynamically adjust their position at different speeds or during braking/cornering to optimize downforce or reduce drag.

- Ground Effect: Utilizing the underside of the car to create low-pressure zones that suck the car to the track, generating massive downforce without relying on large, drag-inducing wings.

- Vortex Generators and Flow Conditioners: Tiny elements that manipulate airflow to improve efficiency, reduce turbulence, or direct air to specific components for cooling.

- Lightweight Aero Structures: Using ultra-light carbon fiber to create complex aerodynamic components that are both strong and precisely shaped.

Aerodynamic breakthroughs from motorsports find their way into efficient road car designs.

C. Materials Science and Manufacturing Techniques

The demand for lighter, stronger, and more durable components pushes the boundaries of material science.

- Carbon Fiber Composites: Extensively used for chassis (monocoques), bodywork, suspension components, and even brake discs due to their incredible strength-to-weight ratio and ability to be molded into complex shapes.

- Additive Manufacturing (3D Printing): Used to rapidly prototype complex parts, create highly optimized components with intricate internal structures, and even produce small batches of functional parts (e.g., lightweight brackets, intricate cooling ducts, unique aerodynamic elements).

- Advanced Alloys: Specialized alloys of aluminum, titanium, and magnesium are developed for high-stress components like engine parts, suspension linkages, and lightweight wheel hubs.

- Ceramic Composites: Used in brake discs (carbon-ceramic) for extreme heat resistance and fade-free stopping power.

- High-Temperature Superalloys: Used in exhaust systems and turbochargers to withstand extreme heat.

- Material Joining Techniques: Innovations in bonding, riveting, and advanced welding techniques to join disparate materials efficiently and strongly.

These advancements make vehicles lighter, stronger, and more resilient.

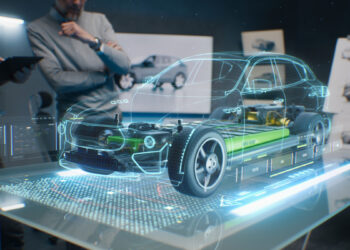

D. Data Analytics and Artificial Intelligence (AI)

Every moment on the track generates vast amounts of data, which is meticulously analyzed to gain a competitive edge.

- Telemetry Systems: Thousands of sensors on a race car stream real-time data (speed, engine RPM, temperature, suspension travel, tire pressure, G-forces) back to the pits, allowing engineers to monitor performance and identify issues instantly.

- Predictive Analytics: AI algorithms analyze historical and real-time data to predict tire degradation, fuel consumption, and component wear, informing race strategy.

- Driver Performance Optimization: AI can analyze driver inputs, comparing them to optimal lines or simulator data, to help drivers refine their technique and find more speed.

- Race Strategy Optimization: Complex AI models process countless variables (weather, tire wear, pit stop times, competitor performance) to determine optimal race strategies in real-time.

- Simulator Technology: Highly realistic racing simulators, powered by vast datasets and advanced physics engines, allow drivers to practice tracks, test setups, and refine skills without burning fuel or risking damage.

- Machine Learning for Design: AI can assist in optimizing designs for weight, strength, and aerodynamics by rapidly exploring millions of design iterations.

Data is the new fuel, and AI is the engine that extracts maximum insight from it.

E. Advanced Simulation and Virtual Testing

Testing increasingly takes place in the digital realm before ever hitting the track.

- Virtual Prototyping: Entire cars and their components are designed and tested virtually using sophisticated CAD (Computer-Aided Design) and CAE (Computer-Aided Engineering) software, reducing the need for expensive physical prototypes.

- Physics-Based Simulations: Highly accurate physics engines simulate every aspect of a car’s behavior – from aerodynamics and suspension dynamics to tire grip and engine performance – allowing engineers to test countless scenarios.

- Driver-in-the-Loop (DiL) Simulators: Extremely realistic simulators where actual drivers can “drive” virtual cars on virtual tracks, providing invaluable feedback to engineers and allowing drivers to practice.

- Virtual Race Strategy: Teams can run hundreds of simulated races with different strategies to identify the optimal approach for a given race scenario.

- Reduced Development Time and Cost: Virtual testing significantly reduces the time and cost associated with physical testing, accelerating the development cycle.

Simulation allows for faster, more cost-effective, and safer development of new technologies.

Motorsports to Road Cars

The innovations proven under the extreme pressures of motorsports frequently find their way into everyday vehicles, benefiting consumers.

A. Powertrain Efficiency and Electrification

- Hybrid Systems: Technologies like regenerative braking, energy recovery systems, and efficient electric motor integration, pioneered in F1 and endurance racing, are now common in hybrid road cars.

- Turbocharging: Advanced turbocharging techniques, honed in rallying and F1 for maximizing power from smaller engines, are widespread in modern road car engines for efficiency and performance.

- Direct Injection: Fuel injection systems that precisely deliver fuel directly into the combustion chamber, boosting power and efficiency, were often developed in racing.

- Advanced Materials: Lightweight materials like aluminum and composites, first extensively used in racing, are now common in road cars for better fuel economy and performance.

Motorsports acts as a proving ground for efficient and powerful propulsion systems.

B. Safety Technologies

Many essential safety features in modern road cars have roots in racing.

- Carbon Fiber Safety Cells: The concept of a rigid, energy-absorbing passenger cell, directly derived from race car monocoques, is fundamental to modern road car safety structures.

- Advanced Braking Systems: High-performance braking systems, including ABS (Anti-lock Braking System) and advanced materials like carbon-ceramic discs, were developed and refined on the track.

- Tire Technology: Innovations in tire compounds, construction, and tread patterns, driven by the demands of racing grip and durability, significantly improve road car tire performance.

- Driver Awareness Systems: Technologies that monitor driver fatigue or distraction, while more primitive in race cars, were influenced by the need to keep drivers alert under extreme conditions.

Motorsports continues to be a driving force for vehicle safety.

C. Aerodynamics and Vehicle Design

The pursuit of aerodynamic efficiency on the track influences road car design.

- Streamlined Shapes: The fundamental understanding of airflow and drag reduction developed in racing influences the sleek, efficient shapes of modern road cars.

- Underbody Aerodynamics: Concepts like flat underbodies and diffusers, first used in racing to reduce drag and generate downforce, are now integrated into many road cars for better stability and fuel economy.

- Spoiler and Wing Design: While exaggerated on race cars, the principles of wing design for downforce are applied in subtle ways to road car spoilers for high-speed stability.

- Cooling System Design: Efficient routing of airflow for cooling engines and brakes in race cars inspires sophisticated cooling solutions in performance road cars.

Aerodynamic lessons from the track make road cars more stable and efficient.

D. Data, Electronics, and Software

The digital revolution on the track is profoundly impacting road car intelligence.

- Telemetry and Diagnostics: The sophisticated real-time data collection and remote diagnostics systems developed for race cars are the precursors to connected car features that monitor vehicle health and enable predictive maintenance.

- Advanced Driver-Assistance Systems (ADAS): The sensors (radar, cameras, lidar) and AI algorithms used for track data acquisition and performance optimization are the very same technologies that power adaptive cruise control, lane-keeping assist, and automatic emergency braking in road cars.

- Engine Control Units (ECUs): The complex, highly optimized ECUs in race cars, which precisely control engine parameters, have driven the development of sophisticated ECUs in road cars for performance and emissions control.

- Digital Displays and User Interfaces: Customizable digital dashboards and intuitive infotainment systems in road cars draw inspiration from the clear, customizable displays in race car cockpits.

Motorsports is a testing ground for the software-defined, intelligent vehicles of tomorrow.ovation

Conclusion

The world of motorsports has always been synonymous with groundbreaking technological progress, and today’s motorsports tech advances are accelerating this legacy at an unprecedented rate. From the silent, brutal power of electric powertrains and the intelligent precision of AI-driven analytics to the microscopic optimizations of advanced materials and aerodynamics, every aspect of racing is being redefined. This isn’t just about winning races; it’s about pushing the boundaries of what’s possible, creating a high-stakes laboratory where innovations are born, proven, and then transferred to shape the future of everyday transportation. As the industry continues its inexorable march towards a cleaner, smarter, and more autonomous future, motorsports will remain at the forefront, a thrilling spectacle of human ingenuity and mechanical prowess, constantly redefining the limits of speed and engineering. The revolution is ongoing, and the checkered flag is nowhere in sight.